A decal is a type of sticker that can be used on many different surfaces, from hard materials such as metal and plastic to soft materials such as fabric and paper. Decals are widely used in many fields, from production and packaging to advertising and decoration.

Decal production process

To produce decals, follow these steps:

Prepare material

First, you need to prepare materials for making decals, including:

Paper: Paper is the most popular material for making decals, there are many different types of paper depending on usage needs, such as couche paper, kraft paper, foil,…

Plastic: Plastic is also a popular material for making decals, there are many different types of plastic depending on usage needs, such as PVC, PET, P,…

Metal: Metal can also be used to make decals, often used for decals that are highly durable, heat-resistant, and water-resistant.

Decal design

After preparing the materials, it is necessary to design the decal. Decal design needs to ensure the following requirements:

Comply with legal regulations: Decal must comply with legal regulations on goods labeling.

Accurate, complete information: Decal must provide all necessary information about the product, including product name, ingredients, uses, instructions for use…

Clear and easy to read: Decals must be designed to be clear and easy to read, helping customers easily find and receive information.

Creative and eye-catching: Decals need to be designed creatively and eye-catching to attract customers’ attention.

Printing decals

After designing the decal, it is necessary to print the decal. Decal printing can be done using many different methods, depending on the type of material and decal quality requirements.

Popular decal printing methods include:

Offset printing: Offset printing is the most popular printing method, can print on many different materials, with high accuracy and beautiful colors.

Flexo printing: Flexo printing is a printing method suitable for small sized decals that require high durability.

Inkjet printing: Inkjet printing is a suitable printing method for decals with complex designs that require high resolution.

Processing decals

After printing, the decal needs to be processed. Decal processing may include the following steps:

Cut decal: Cut decal to desired size and shape.

Decal gloss: Decal gloss helps the decal have better shine and waterproofness.

Needle pressing: Needle pressing makes the decal more luxurious and sophisticated.

Check and package the decal

After processing, it is necessary to check the decal to ensure quality. Decals that meet requirements will be packaged and delivered to customers.

To produce effective decals, attention should be paid to the following factors:

Material quality: The material used to make the decal needs to be of good quality, ensuring the durability and aesthetics of the decal.

Decal design: Decal design needs to be creative, eye-catching and suitable for the intended use.

Printing method: Printing method needs to match the type of material and decal quality requirements.

Decal processing: Decal processing needs to be done carefully, ensuring the decal is of good quality.

Producing decals according to an effective process will help businesses create high-quality decals, meet customer needs, and contribute to improving business efficiency.

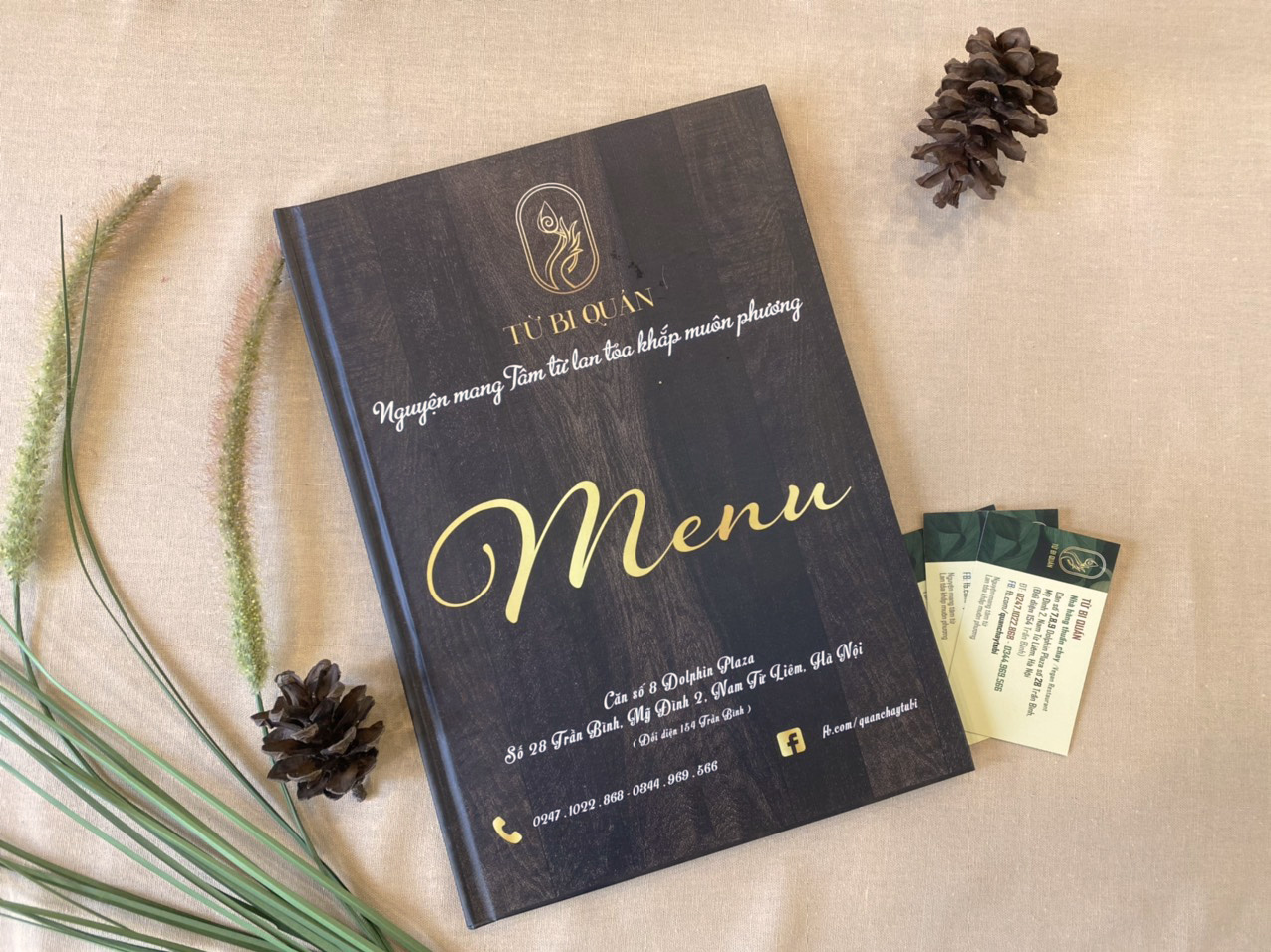

TAN VIEN PRINTING AND BUDDHIST CULTURAL PRODUCTS COMPANY LIMITED

Address: Căn 08, Dolphin Plaza, 28 Trần Bình, Mỹ Đình 2, Nam Từ Liêm, Hà Nội

Hotline: 0348.793.698 – 0825.727.265

Website: https://intanvien.com/

Fanpage: https://www.facebook.com/CT.VHP.PG.TanVien

Youtube: https://www.youtube.com/@CongTyTNHHVHPPhatGiaoTanVien